Stainless Steel: Applications for Every Industry

Aug 21, 2014

Have you ever thought about what life would be like if all the stainless steel in the world disappeared?

Nuclear power plants would go into meltdown. Airplanes would fall from the sky, and water supplies would become contaminated. S

kyscrapers like the Empire State Building would look like skeletons, and weapons would fall apart. Homes everywhere would be without p

lumbing, factories would halt production, and people would have to rely on silver or wooden eating utensils once more.

In this scenario, it’s easy to see how vital stainless steel has become in our world’s daily operations. The applications of stainless stee

l are far-reaching, and the list of benefits is endless.

Why Is Stainless Steel Better?

The nature of stainless steel is such that it can long outlast hundreds of other materials.

For instance, picture building an outdoor structure out of plain steel in the middle of a rainforest. The moisture and humidity would

rust and corrode the metal, reducing it to a useless pile in a few months. Build the same structure from stainless steel, and it’s likely you’ll

see it looking as good as new even 500 years later.

This translates into some essential qualities for many different industries. Some of the other standout qualities of stainless steel inclu

de the following:

- Self-healing – Just like a comic book superhero, stainless steel can repair itself when scratched. The natural surfa

ce sealant, a result of oxidization, reforms over the scratch before corrosion can occur. This makes it invaluable for use in tall buildings an

d structures where regular maintenance would be difficult. - Corrosion resistance -The oxidization layer that clings to stainless steel protects it from natural decay. This is es

pecially useful when transporting corrosive liquids that would otherwise be contaminated by their containers. - Sustainability – 100% of stainless steel is recyclable. This makes it sustainable, and it reduces environmental imp

act. Its durability also minimizes the need for expensive repairs and maintenance throughout its long life. - Withstanding extreme temperatures – Stainless steel can endure exposure to extreme high or low temperatures

for long stretches of time, depending on the alloy grade. That’s one of the reasons the scientific, medical, and food industries find it so u

seful. - Easy fabrication – Most stainless steel alloys are easy to work with when forming, welding, or cutting, which help

s to lower production costs. It can also fit almost any kind of texture or appearance, although rougher surfacing does sacrifice some dura

bility.

Who Uses Stainless Steel?

It’s hard to go anywhere without seeing some form of stainless steel in use. In fact, you might have to tra

vel to the middle of a desert or mountain range to avoid it. Stainless steel is in everything from pins to space shuttles, and its versatility e

nsures it will be a key component for many more things in the future.

Here’s a quick look at some of the industries that regularly rely on steel.

- Aerospace – Various aircraft depend on the high heat and cold resistance properties found in stainless ste

el. Whether it’s the freezing vacuum of space or the dramatic heat of re-entry, rocket engines in particular tend to put this material throu

gh its paces. - Water/waste processing – Corrosion resistance is essential to the water treatment and waste managemen

t processes. Stainless steel is easier to clean and resists corrosion better than most other metals-even with regular exposure to corrosive

elements. - Nuclear power plants – A typical nuclear power plant depends on stainless steel for its safe operation and

longevity. The properties of stainless steel-its strength, corrosion resistance, and durability-make it the best choice for use in highly delica

te, extreme, and potentially volatile conditions. - Scientific labs – In an environment where sterility is of the utmost importance, stainless steel plays a cruci

al role. Its nonporous surface and ease of sterilization has made it a preference even above aluminum for most laboratories. - Commercial kitchens – From cutlery to saucepans to sinks, commercial kitchens depend on steel due to its abilit

y to withstand hot and cold temperatures. Additionally, steel’s corrosive-resistant surface makes it ideal for holding foods that wo

uld otherwise damage their containers. And because steel is easy to clean, it will reduce bacteria buildup that could cause food poisoning. - Other applications – Paper manufacturing uses stainless steel because it will not contaminate the final pro

duct, and resists the corrosive properties of the chemicals used in the process. Many other areas such as the pharmaceutical and chemical

industries use it for the same reasons, as well as its atypical endurance.

If you’re involved in any kind of industry, chances are likely that you use a form of stainless steel in some capacity every day. It’s eas

y to see how deeply integrated it has become in societies throughout the world. Thankfully, we shouldn’t ever have to worry about the

mass disappearance of a metal alloy. Stainless steel is here to stay, and the world functions much better for it.

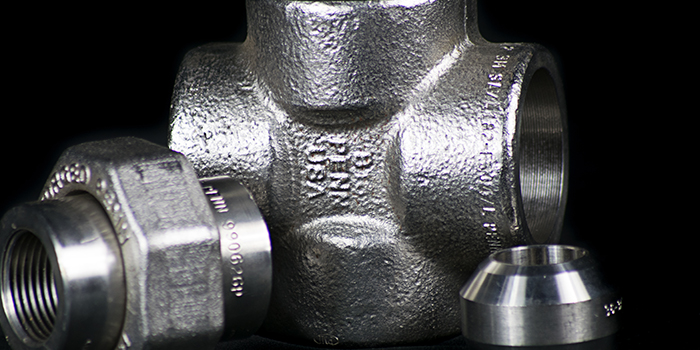

About James Duva Inc.

Since 1978, James Duva Inc. has been your trusted source for stainless steel and high-nickel alloy industrial products. Whether you’re in the water treatment, process or power industry, we pride ourselves on always having what you need. Say goodbye to your sourcing problems with just one call to James Duva.